The XCMG-customized Cummins low-speed, high-torque engine offers fast response, ample power reserve, and an 8% increase in torque, ensuring no stalling even under heavy loads.

Equipped with an electronically controlled positive-flow hydraulic system, the slave pump independently controls the main pump and large-diameter main valve. XCMG’s unique “Feed Forward Intelligent Control System (PIC)” platform technology improves engine transient response time by over 90%, resulting in faster overall machine response.

The main pump utilizes a high-pressure rotary mechanism, increasing bearing life by 20%. A 1.4m³ reinforced bucket, designed to conform to the digging trajectory, is standard, reducing digging resistance.

The vehicle-level NVH design is optimized, along with a luxurious, large-size suspended seat that provides a 10% increase in visibility and meets FOPS/ROPS safety requirements. The instrument panel features an 8-inch high-resolution touchscreen, push-button start, and integrated Bluetooth, radio, and air conditioning controls.

Using CAN communication and CFD-optimized air flow, the air conditioning system increases cooling capacity by 10%, heating capacity by 8%, and ventilation efficiency by 10%.

The hood has a wide opening angle and is supported by a gas spring, allowing for easy opening and closing. The hood is spacious and easily accessible for maintenance.

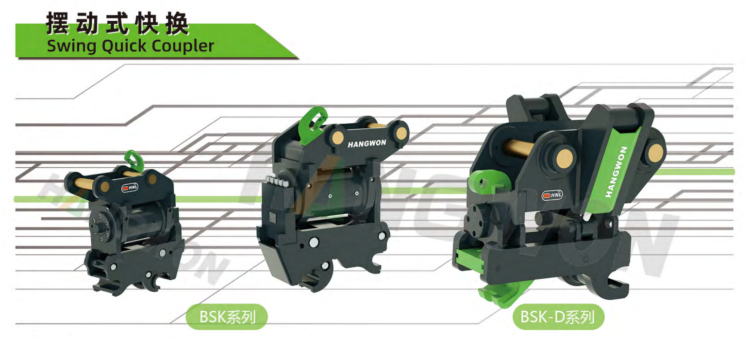

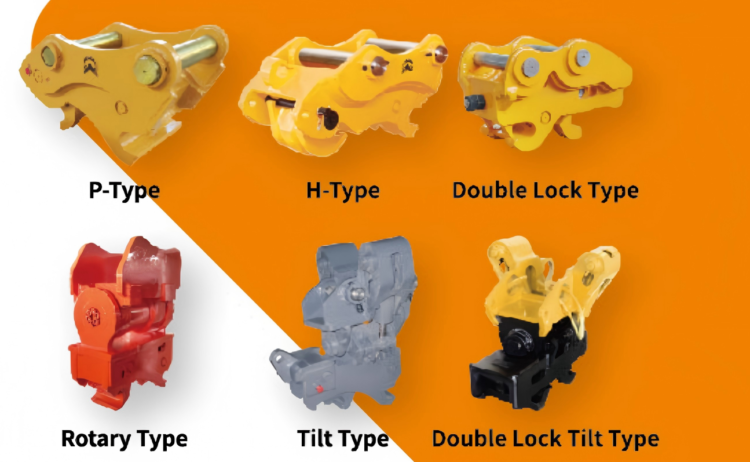

The fuel filter, oil filter, and pilot filter are concentrated in the pump room for easy disassembly and maintenance. The independently developed multi-functional machine intelligent control system allows for optional installation of crushing pipes, breaker hammers, mechanical quick change, hydraulic quick change, rubber track blocks, etc. to expand the machine’s application areas.